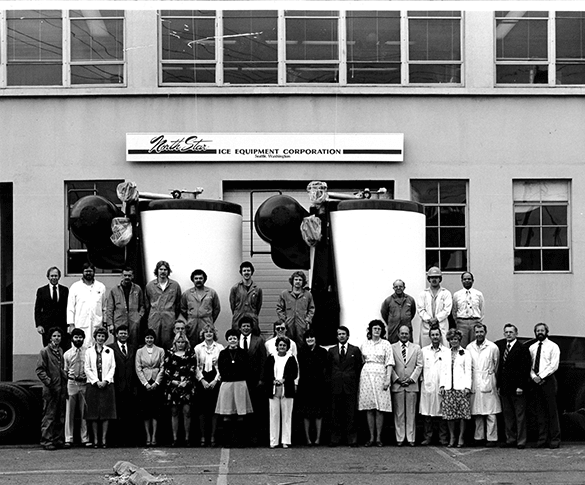

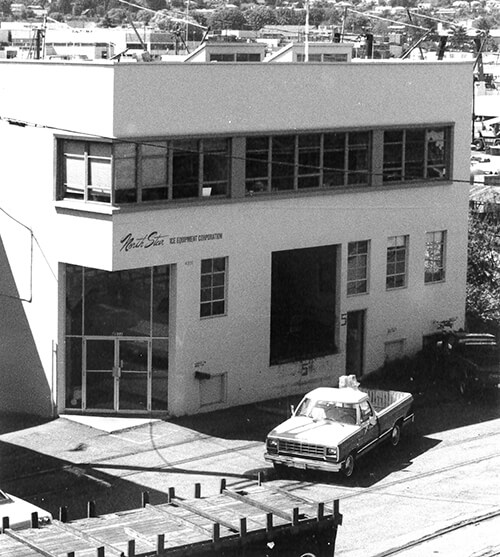

providing ice solutions for over 65 years

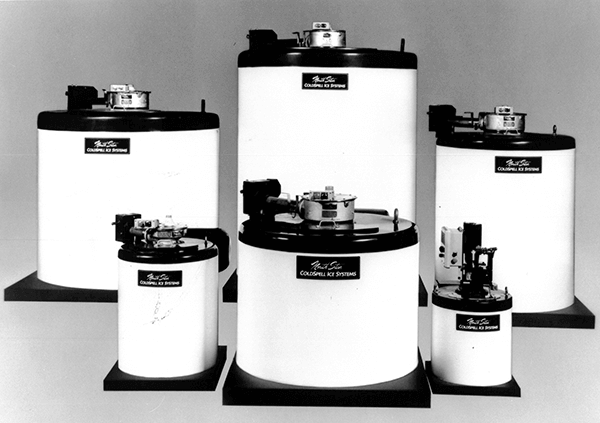

North Star Ice Equipment has built a worldwide reputation for the design and manufacture of high-capacity, industrial flake ice machines. The company’s primary product line is a drum ice maker with a vertical stationary evaporator, which is available in six models with capacities that range between 2 and 56 tons per day. Machines can also be combined to increase capacity. North Star ice makers are well known for their heavy-duty construction and dependability.

PIONEERS OF FLAKE ICE

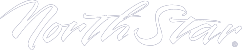

During World War II, Halibut Liver Oil Producers of Seattle, Washington became the world’s largest producer of Vitamin A, derived from cod liver oil. As production increased, cod livers were shipped to Seattle for oil production from as far away as Mexico and the Aleutian Islands, resulting in irregular deliveries throughout the year. In 1945, the company decided to construct a cold storage facility so that processing could be done in an orderly basis. Foreseeing constantly increasing labor costs, the company departed from the usual pattern of a block ice plant and ordered flake ice making equipment together with a mechanical ice delivery system.

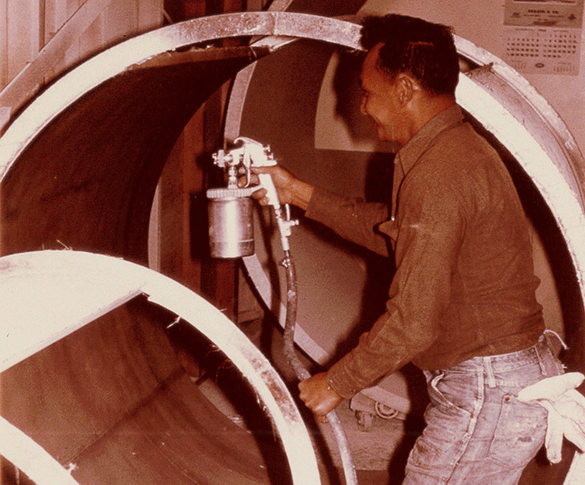

Although the ice produced was of reasonable quality, the initial machines installed were mechanically unreliable. As a result, in 1949, the company undertook development of a new innovative type of ice maker to produce dry, sub-cooled, “flake ice.” The newly designed machines were not only more dependable, but the flake ice they produced was far superior in cooling performance and handling than the other types of ice used at the time.

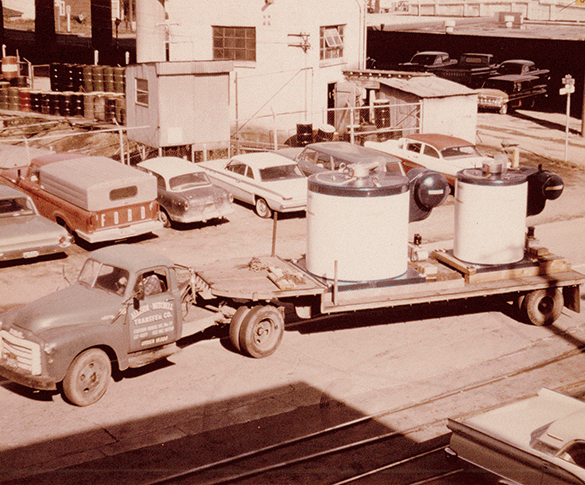

Halibut Liver Oil Producers felt this ice machine would have applications in the wider fishing industry, and the company that was to become North Star was created as a separate entity. The first flake ice machine sold was installed in Nova Scotia, Canada in 1951.

Today, North Star has flake ice machines and ice handling systems operating worldwide in the fishing, aquaculture, concrete, meat and poultry processing, chemical, packaged ice, baking, produce, and a variety of other industries.