Select menu

Ice Where and When It’s Needed

Once ice is produced and stored, it needs to be delivered to remote icing stations or other use points. With our decades of experience, North Star can assist customers in designing the ice delivery system that is right for them.

Equipment Features

North Star Ice Delivery System Features

North Star Ice Delivery System Features

- Screw conveyors and pneumatic delivery systems available

- Both types deliver up to 40 tons (36 MT) of ice per hour to one or more use points.

- All deliveries can be remotely controlled and volumetrically metered and recorded within 2% accuracy at the storage bin, the remote stations, and the control centers.

- The operation of the entire delivery system is controlled by the central ice plant control panel.

Specifications

Also view the specifications sheets for Buffer Tanks and Concrete Cooling Buffer Tanks.

-

Screw Conveying Systems

Most economical for horizontal deliveries of up to approximately 150 feet (46 meters).

Can be installed at angles up to 30 degrees from horizontal.

Manual or automatic curved slide gates provide intermediate in-line discharge points.

Available in either standard hot dip galvanized or optional stainless steel finish, with or without factory-applied insulation.

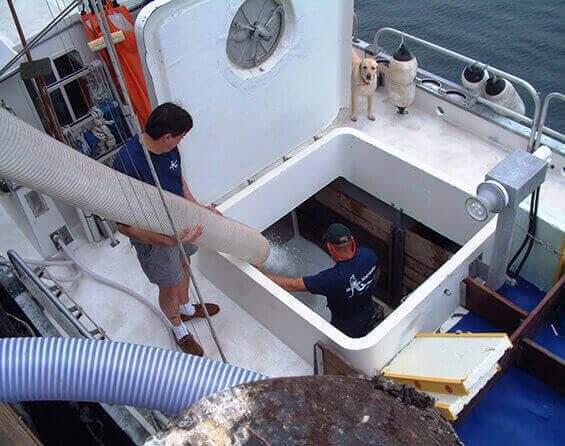

Telescoping chutes or hoses can be provided at the conveyor discharge to accommodate variations in tidal elevation, placement, or size of the ice container (vessel, railroad car, or truck.)

-

Pneumatic Delivery Systems

Most economical when conveying ice over long distances, when multiple icing stations are required, when the ice must be greatly elevated, or when ice must be delivered at high velocity.

Standard systems discharge ice up to 500 feet (152 meters) away from the storage bin. North Star has successfully conveyed ice over 1,200 feet (366 meters) from the ice plant. We have pneumatic delivery systems of 400 to 800 feet (122 to 244 meters) in multiple directions from the ice plant that are currently serving the chemical, concrete cooling, and fishing industries.

Automatic diverter valves are available - electric lineal actuated or air actuated to provide multiple delivery points.

Provides high velocity discharge to trucks, boats or railcars; or low velocity, gravity discharge using a cyclone receiver for totes, case ice dispensers or buffer tanks.

Helpful Technical Information

Use the Capacity Calculator below to size the correct ice maker for your project. Download helpful brochures, specification sheets, and other technical data in our Resources Library.