Select menu

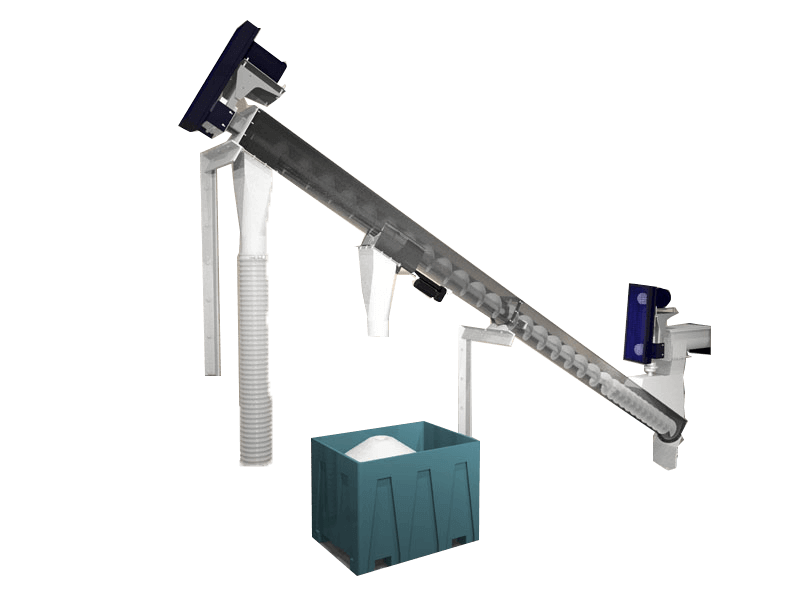

Screw Conveying Systems

North Star screw conveyor systems are custom-built for any industry to deliver any type of ice. Screw conveyor systems deliver quality, usable ice by elevating and horizontally moving the ice to your delivery points. Screw conveying is the economical choice when the total conveying distance is less than 150 feet (40 meters).

Equipment Features

Standard Features

- Most economical for horizontal deliveries of up to approximately 150 feet (46 meters)

- Can be installed at angles up to 30 degrees from horizontal

- Manual or automatic curved slide gates provide intermediate in-line discharge points

- Available in either standard hot dip galvanized or optional stainless steel finish

- Screw conveyor sections normally come in lengths of 10 or 12 feet (3 or 4 meters) depending on the particular application

- All screw conveyors include trough-supporting feet and flat trough covers

- Telescoping chutes or hoses can be provided at the conveyor discharge to accommodate variations in tidal elevation, placement, or size of the ice container (vessel, railroad car, or truck).

- Screw conveyor sections are coupled together using high strength fasteners with vex nuts to prevent bolt loosening during operation

Screw Conveyor Options

- 100% Stainless Steel screw conveyors available

- Can be manufactured with factory-supplied insulation

- Half-pitch flighting with volumetric metering (within 2% accuracy)

- Shrouded covers for incline conveyors

Helpful Technical Information

Use the Capacity Calculator below to size the correct ice maker for your project. Download helpful brochures, specification sheets, and other technical data in our Resources Library.